Our Company is primarily engaged in the manufacture of sugar. We also manufacture other allied products like Rectified Spirits, Extra-Neutral Spirits, Indian Made Liquor, Vinegar, Compost, Carbon dioxide (CO2), etc. and also are engaged in the generation of Power. Based on the products portfolio our Company offers, we have 5 major segments including Sugar, Co-Generation, Distillery, Indian Made Liquor (IML) and Vinegar. Our Company has an integrated production and manufacturing facility for all our products and by-products located at Bellad Bagewadi, Belgaum District, Karnataka 591 305. The location where our integrated sugar production unit is situated has been designated as one of the High Recovery Zones for sugar production by the Government of India.

In the year 2001, we commenced operations of manufacture of Distillery products such as Ethanol, Rectified Spirit and Extra Neutral Spirit. In the year 2006, our Company implemented backward integration and began commercial operations for Sugar manufacture from sugarcane, along with Co-Generation capabilities. During the year 2008, we began bottling of Indian Made Liquor.

Currently, our integrated unit processes sugarcanes to produce sugar and the by-products are used to generate electricity for captive use and commercial sale, manufacture rectified spirit, ENA, IML, Vinegar, Press-mud and Compost. Over the years, we have expanded the production / manufacturing capacities of all our products. Our present licensed manufacturing capacity for our various products is given below:

| Sr. No. | Product | Current Approved Capacity |

| 1 | Sugar | 2,42,000 Tons / Year |

| 2 | Bagasse | 6,60,000 Tons / Year |

| 3 | Molasses | 88,000 Tons / Year |

| 4 | Rectified Spirit | 30,000 KL / Year |

| 5 | Extra Neutral Alcohol (ENA) | 21,000 KL / Year |

| 6 | Industrial Ethanol | 90,000 KL / Year |

| 7 | Electricity | 4,96,800 MW / Hr |

| 8 | Brewed Vinegar | 34,500 Ltrs. / Day |

(1) The above licensed capacities are equivalent to a total Sugarcane crushing capacity of 11,000 TCD working for approximately 200 days per year (Crushing Season) at an average 11% recovery rate for sugar, 30% for Bagasse and 4% for Molasses.

Production of sugar, power and distillery products requires our Company to adopt stringent Quality Assurance and Quality Control standards (QA/QC). We have set-up indigenous laboratories for each department which ensures that quality of raw material used in the production process and also the finished goods delivered to our customers is subject to various tests. To access and facilitate compliance with applicable requirements, we regularly review our quality systems to determine their effectiveness and identify areas for improvement. This helps in improving our procurement process thus reducing wastages, returns and other related costs.

During the production of sugar; bagasse and molasses are produced which are the basic raw materials for power generation and Distillery (Spirit) manufacturing unit, respectively. The sugar unit of our integrated production facility first crushes sugarcane to extract juice and processes the juice to produce sugar. The sugar manufactured is then graded and packed based on the size of crystals and quality of the sugarcane. During the last fiscal year we produced 32,170 tonnes of sugar. After extracting the juice from sugarcane, the residual fibre leftover called Bagasse is used as a fuel for power generation. The molasses used in the process of sugar production is fermented and distilled to manufacture various spirits (Rectified Spirit and Extra Neutral Spirit) and IML in the distillery unit of our integrated production and manufacturing facility.

Bagasse is the fibrous residual matter used as a bio-fuel to generate steam for turning turbines to generate electricity. We obtain enough Bagasse during the crushing seasons, such that the electricity produced is used not just for captive consumption, but also for sale. For electricity generated over and above our captive consumption, we have entered into Power Purchase Agreements with 5 electricity distribution companies in Karnataka to supply a total of 22.4 MW. It is possible that during the year we may produce surplus energy and supply the surplus energy to other Companies / Industries based on demand.

Molasses is the viscous product resultant of refining sugarcane juice. Molasses, which forms the primary raw material for the distillery unit, is fermented, distilled and made to undergo various processes for making rectified spirit and extra neutral spirit. Rectified Spirit is processed to manufacture Industrial Vinegar. Extra- Neutral spirit is further processed for manufacture of IML products. The Extra-Neutral spirit is blended to manufacture Whiskey which is sold by us under our various brands like “Our Choice”, “Your Choice”, District-1 and VSL Black. During the last financial year, we manufactured approximately 1,890 boxes of IML, 4,098 KL of Industrial Vinegar, 8,838 KL of Rectified Spirit and 2,269 KL of Extra-Neutral Spirit.

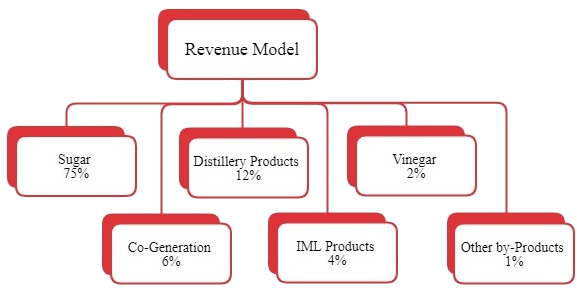

The Revenue Model of the Company for March 31, 2017 is as below:

Our income from the sugar business formed approximately 75%, 74% and 68% of our total net sales in the F. Y. 2017, F. Y. 2016 and F. Y. 2015, respectively; Income from the co-generation business formed 6%, 8% and 13% of our total sales in the F. Y. 2017, F. Y. 2016 and F. Y. 2015, respectively; Income from the Distillery business formed 12%, 8% and 10% of our total sales in the F. Y. 2017, F. Y. 2016 and F. Y. 2015, respectively; whereas, Income from the IML business formed 4%, 6% and 8% of our total sales in the F. Y. 2017, F. Y. 2016 and F. Y. 2015, respectively.

Our revenue from operations for the last 3 years i.e. F. Y. 2014-15, 2015-16 and 2016-17 were ₹ 27,981.43 lakhs, ₹ 33,564.66 lakhs and ₹ 28,405.06 lakhs. For the same period, our net profits have increased from a loss of ₹ 341.12 lakhs in F. Y. 2014-2015 to a profit of ₹ 441.46 lakhs in F. Y. 2015-16 and further to a profit of ₹ 877.88 lakhs in F. Y. 2016-17. Our revenue and net profit after tax for the period ended September 30, 2017 were ₹ ______ lakhs and ₹ ______ lakhs respectively.